Rethinking healthcare across Nordic countries

The Nordic Sales Team brings Ambu's mission to the four Nordic countries: Denmark, Norway, Sweden, and Finland. Since 1937, our Sales Representatives and Customer Service Professionals have been providing dedicated services for each country. Located in our headquarters building in Ballerup, Denmark, The Nordic Team works closely with Ambu’s internal R&D department. Together, we continue to redefine possibilities in single-use endoscopy, anaesthesia and patient monitoring solutions.

Every case, every day

A single-use ureteroscope solution that matches your current OR setup and makes it possible continue to perform procedures confidently without worrying about breakage and without having to compromise on performance.

Discover Ambu® aScope™ 5 Uretero, a single-use solution that offers clear imaging and excellent manoeuvrability with an integrated endoscopy system that is easy to learn and use. A solution with Electronic Health Record (EHR) integration, which makes documentation smooth and efficient.

Perform procedures confidently without worrying about breakage

A solution built for the endourology experience

The world’s first ureteroscope with bioplastic material

Taking leaps towards a sustainable future

We rethink MedTech solutions, for the benefit of healthcare professionals, patients, and our planet. With the introduction of bioplastics, circular packaging, and recycling programs, we continuously lower our environmental footprint.

Targets we're meeting in 2024

Circular products

- Redesign all cuff protectors for Ambu´s laryngeal masks so they contain less material

- Replace all Ambu laryngeal mask cuff protectors to a 100% bioplastic

- Introducng bioplastic has lowered our carbon footprint in endoscope handles production by 70%

Circular packaging

- Secondary packaging (product cardboard boxes) is now 100% recyclable for all Ambu products

Recycling programs

Take back solutions and recycling pilot projects ongoing in Germany and UK for scopes

Total global share of recycled waste in 2022/23 is 46%

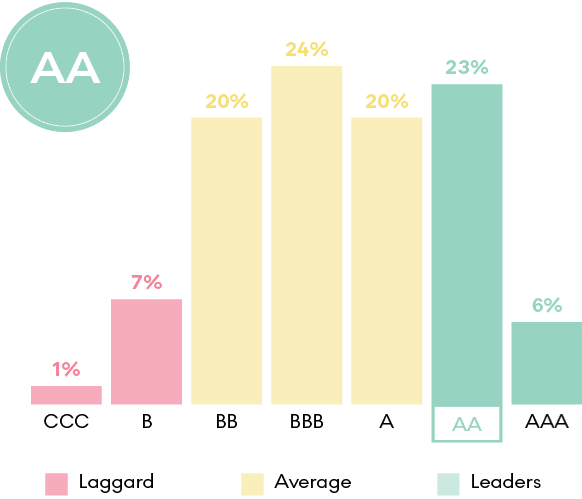

MSCI Rating

An MSCI ESG Rating measures a company’s resilience to longterm industry material environmental, social and governance (ESG) risks. We’re proud and happy to share that Ambu maintains the AA ranking since 2021, and we uphold our dedication to work towards achieving a more sustainable healthcare.

How a circular approach to packaging lowers our carbon footprint in Aura™ laryngeal masks?

Circularity aims to create a closed-loop system where waste is minimised and materials are recycled.

Our packaging is shrinking

To contribute to our carbon emissions reduction efforts, we have focused on minimizing our packaging size. This approach not only decreases the quantity of materials utilized but also optimizes transport space, enabling us to pack more efficiently, utilize transportation resources more effectively, and ultimately reduce our overall environmental footprint.

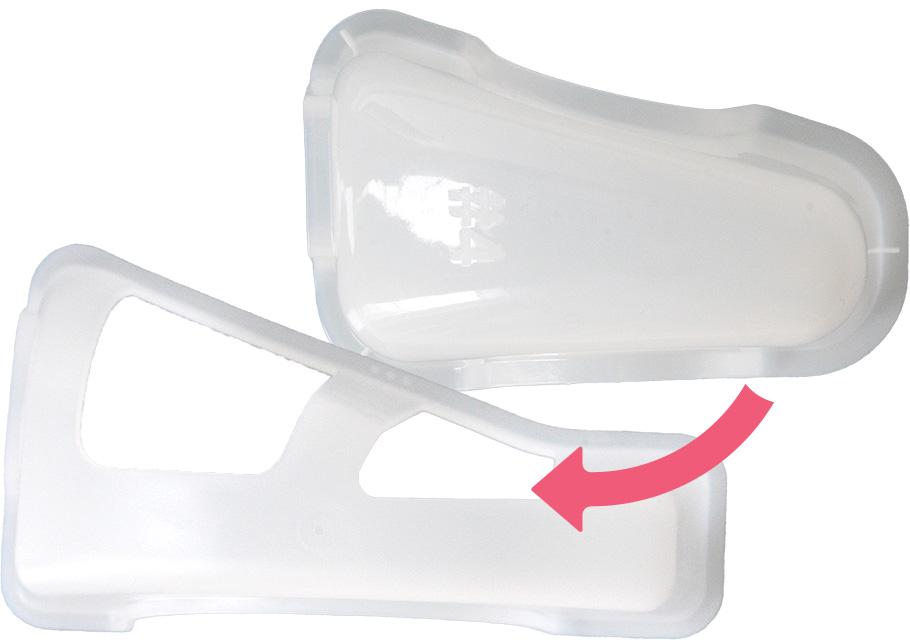

Minimal waste; Maximum protection

Not only are we reducing the size of the pouches that the Aura™ range comes in, we are also reducing the plastic used in the cuff protector which is being made as a more cage like structure reducing the amount of plastic used overall.

Marrying sustainability with innovation

In order to lower our carbon footprint, the HDPE plastic used in our cuff protectors is now made in 100% of bioplastic raw material instead of conventional fossil-based HDPE plastic.

3 facts about bioplastics and Ambu laryngeal masks

- The Aura™ laryngeal mask cuff protectors are made of 100% bioplastic material

While the quality and performance of the masks remain the same, the bioplastic material used in the cuff protectors have a lower carbon footprint than purely fossil-based plastics. - Introducing bioplastics reduces our use of fossil-based virgin plastic

The bioplastic material used in our cuff protectors is sourced from a mix of fossil-based and second-generation bio-based feedstock, such as used cooking oil. This practice reduces our use of fossil-based virgin plastic - without competing with food and agriculture production. - Bioplastic has a significantly lower carbon footprint

Bio-attributed HDPE plastic emits 65% less CO2e compared to purely fossil-based HDPE plastic*.

*Based on cradle to grave Life Cycle Assessments on the raw material from supplier. This does not translate to 65% savings for the carbon footprint of the finished good’s full lifecycle. Savings on the raw materials are 6 g to 55 g CO2e per finished good depending on mask size and type.

Case studies

Learn how Ambu drives change in healthcare

The Impact of ECG Sensor Design on Signal Noise

Marie Riis Dammeyer, Msc., R&D Engineer & Daniel Hansen, Phd, R&D Engineer

August 2021, Ambu A/S

A comparative study of ECG electrodes with either center or offset connector demonstrates that electrodes with an offset connector mitigate the impact of pulling the lead wire and pressing the connector on signal quality to a large extent.

Download whitepaper

Life Cycle Assessment of Reusable and Disposable Cystoscopes: A Path to Greener Urological Procedures

Baboudjian, Et Al.

Euro Uro Focus, 2022 Dec

- Transitioning from reusable to single-use can reduce environmental footprint

- Reprocessing of reusable cystoscopes, alone, had greater impact than whole lifespan of aScope 4 Cysto

- Due to lack of manufacturer data for parts of the lifespan other than reprocessing, the environmental impact of reusable cystoscopes was considered close to zero

Read more

Contact us

Call your local customer service

We will gladly answer your questions every working day between 8 AM and 4 PM. You are always welcome to write us an email at nordicmarketing@ambu.com. We will reply maximum in a week.

Denmark

Ambu Denmark

Baltorpbakken 13

DK-2750 Ballerup

Finland

Ambu

Sivuliike Suomessa

PO Box 27

FI-02211 Espoo

Norway

Ambu Norge Filial

Postboks 107- Sentrum

NO-0102 Oslo

Sweden

Ambu AS Danmark, filial

Box 22 155

SE-250 23 Helsingborg